What we do

At AquaGrow Technologies we are developing a pioneering approach to scalable modular indoor farming that enables growing fresh food where there is no farmland, no electrical grid, and no distribution infrastructure. AquaGrowTech Farms are engineered to be energy independent and housed in a 45x10x10 ft cargo containers, to provide food security in a globally changing climate, extreme weather patterns and growing population.

How we do it

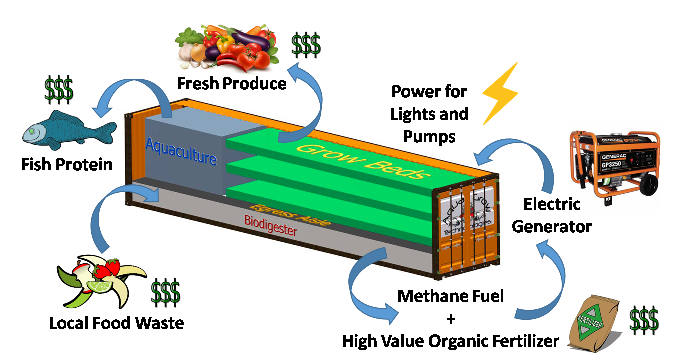

We achieve this by synergistic integration of the best sustainable practices into hi-tech high efficiency farms: modular designs for mobile distributed year-round food production, aquaponic farming for the simultaneous production of protein and fresh produce, and a waste-to-energy biodigester conversion unit capable of powering farm operations.

In aquaponic farming systems affluent from aquaculture (fish or shrimp) is used to supply nutrients to plants, and the depleted water is then recirculated to the aquaculture tanks. This closed loop farming system is suitable for the production of a nutritionally balanced diet, uses 90% less water than conventional farming, offers efficient use of land and eliminates the need for synthetic fertilizers, instead, the main source of plant nutrients originates from the fish feed.

To power the aquaponic farm we designed and patented novel ergonomic design for anaerobic biodigester which breaks down food waste into methane fuel which is used to generate electricity for the container farm, as well as nutrient rich fertilizer. The digester is designed to provide sufficient power to operate the container without the electrical grid. Although part of a single container unit, the digester is completely isolated from the aquaponic system with input and output feeds on the outside of the container.

Unique Features of AquaGrowTech Container Farms:

|

- Innovative sustainable approach to indoor farming - Scaled anaerobic biodigester unit for energy autonomy - Ergonomic designs for aquaponic module - Automated monitoring and system balance controls - Thermally stable enclosure |

|

The five revenue streams from the container farm (fresh produce, fish/shrimp, electrical power, food waste tipping fee and organic fertilizer) culminate into direct benefits for the local communities. The unit is designed annually produces 14500 lb of fresh produce, 1100 lb of fish, 110 MWh of energy, 45 tons of high value fertilizer and will eliminate 155 tons of food waste normally destined to for a landfill. Our designs are flexible, scale-able and mobile. Single container unit will produce $40-80K in profits with payback period of 2-3 years. Small scale of the containerized aquaponic farms lowers the entry barrier and the risks for new farmers, communities and non-profit organization. Containerized aquaponic farms are transportable, can be relocated closer to the customers if necessary.